Point Cloud Scans in the Steel Industry: Precision Engineering for the Modern Age

- Jesse Quiroga

- Nov 29, 2023

- 5 min read

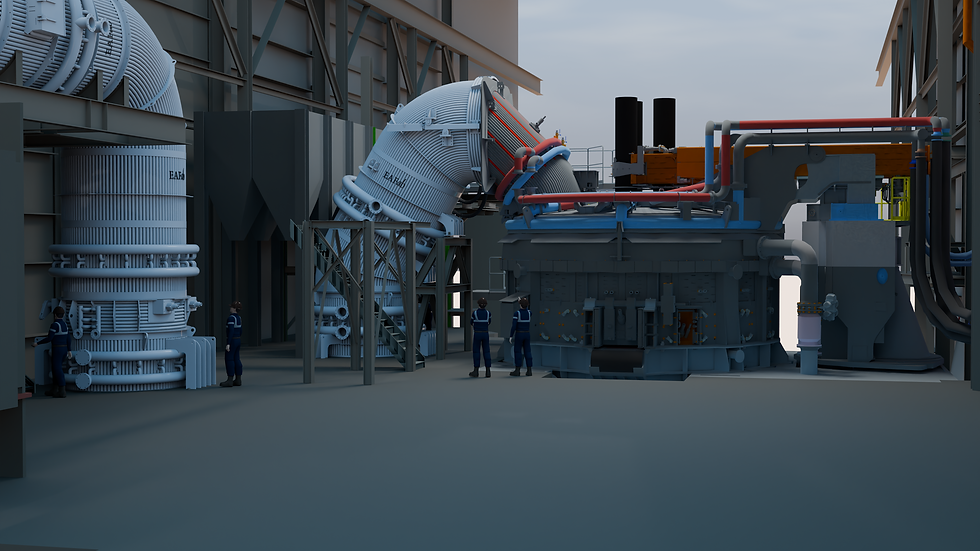

Today, when engineering precision is paramount, the steel industry finds itself increasingly reliant on advanced technologies to meet the rigorous standards of today’s world. Among these technologies, Point Cloud Scans (PCS) stand out as a powerful tool. They have the potential to revolutionize the way we conceive, design, and produce steel. As the industry continues to evolve over decades, understanding and embracing PCS have become a game-changer.

What is a Point Cloud Scan?

A point cloud is a collection of data points in a three-dimensional coordinate system. These

points, which can number in the millions or even billions, represent the external surfaces of objects. When we talk about a Point Cloud Scan, we refer to the process by which these points are collected, typically using laser scanners or other specialized equipment.

Performing a point cloud scan typically requires a small team of engineers to be on-site for the duration of the scan. This normally takes place during a single shift but can be extended as needed depending on the size of the project. Prior to arrival, the scanned areas should be cleared of all major dust and debris. The cleaner the area is, the more accurate the scan will be. It is also important to limit movement during the scanning process because excessive movement can create blurry or obscured areas in the point cloud. Ultimately, an accurate scan can help avoid costly downtime during an installation.

Importance in the Engineering Process

Accuracy and Precision: In the steel industry, where structures need to withstand enormous stresses and loads, accuracy isn't just a luxury—it's essential. A tiny mistake in measurements can lead to catastrophic failures. PCS offers an unprecedented level of accuracy, capturing every nuance of a structure or space.

Pinpoint Interferences: This method accounts for elements that are beyond the mechanical drawings. This can include safety features such as handrails, platforms, chains, hoses, etc; as well as any hydraulics and unforeseen operational actions, effectively serving as an X-ray view of the surroundings. It ensures that all external factors are considered and adjusted in the design to enable a smooth installation and operational process.

Efficiency: Traditional measuring methods can be time-consuming and labor-intensive. PCS, on the other hand, can quickly capture vast amounts of data, saving time and reducing labor costs.

Versatility: Whether you're working with a pre-existing structure or creating something entirely new, point clouds can be employed at multiple stages of the engineering process. They help visualize mounting points, electrode alignment, off-gas locations, elevations, and inspection cores, ensuring precision in our projects. Ultimately, it aids in understanding the mill environment, informing our design decisions, and ensuring flawless execution on the day of installation.

Precision and the "Right Fit" Installment

The term "right fit" is not foreign to the steel industry —everything must be precisely aligned for a mill to operate effectively and efficiently. After an area of the mill has been scanned, its point cloud can be turned into a "digital twin," a 3D model that is an exact replica of the scanned area. Every new product can then be simulated with the point cloud to make sure it fits and functions correctly with all of the existing equipment prior to fabrication.

Engineers can instantly compare their work to the digital model throughout the design process and receive instantaneous feedback in the event of an interference or if the alignment is off. PCS's detailed information can be utilized to make equipment that fits every melt shop's precise and unique specifications.

Uses in the Steel Sector

The engineering and fabrication of large-scale equipment and mill infrastructure can benefit greatly from PCS. It is vital to see how different parts of an assembly will interact with one another, and pre-determine and test for any unforeseen on-site interferences.

We use point cloud scans for a variety of projects, including Ladles, Ladle Metallurgical Furnaces (LMFs), Silos, and other installations. They are especially useful in LMF projects due to the complexity of the area.

There is minimal space for error when replacing equipment in an active mill. To ensure that any expansions or restorations are in keeping with the original, PCS helps record the finer characteristics of surrounding equipment.

Hope for a Promising Tomorrow

Each year, engineering technology improves, becoming more widely available and fundamental to the steel industry. Point Clouds are more than a passing fad in technology. They signify an advancement in the way we approach engineering and precision.

EAFab promises a better, safer, and more efficient future in steel, where accuracy and longevity are of the utmost importance. Tools like PCS guarantee that we are building on a solid ground of precision and perfection as we continue to expand the boundaries of our industry.

Point Cloud Scan Services with EAFab

The need for accuracy and efficiency in the steel business is greater than ever in today's fast-paced technological world. Point Cloud Scans (PCS) are extremely helpful since they ensure precision, cut down on wasteful mistakes, and save time and money.

Pedro Quiroga, along with his team at EAFab, recognizes the value PCS brings to the table. Testament to their commitment, EAFab goes the extra mile—literally. Pedro and his team recently traveled to a customer's location to conduct an in-depth scan of their mill. This dedication not only ensures accurate data collection but also fosters a deep understanding of the unique challenges and requirements of each project.

But the service doesn't stop at merely scanning. Armed with this high-resolution software and on-site insights, EAFab's engineers can hone equipment designs with unparalleled accuracy. The promise? Equipment that doesn’t just fit, but is proven to excel in its operational environment. The result is machinery that seamlessly integrates into the mill, ensuring peak performance and optimal output. Here’s what partnering with EAFab ensures:

On-Site Data Collection: By visiting your location, EAFab ensures that no detail, however minute, is overlooked.

Tailored Solutions: Every mill is unique, and so should its solutions. EAFab’s approach ensures designs are bespoke, fitting the distinct requirements of each project.

Efficient Installation: With the accuracy of PCS, the need for post-installation adjustments and modifications is drastically reduced, ensuring timely project completion.

Optimal Operation: EAFab’s meticulous design process ensures that the equipment operates at its highest capacity, bringing tangible gains in productivity and efficiency.

Future Proofing: In addition, the Point Cloud data is shared with our customers upon completion, empowering them to leverage this valuable resource for future projects, and display EAFab’s commitment to transparency.

So, why wait? If precision, efficiency, and performance are what you seek, it's time to bring in the experts. Get in touch with an EAFab representative today and let us redefine excellence for you. With EAFab's Point Cloud services, welcome a future of engineering perfection.

.png)

Comments