The Scrap Bucket at EAFab

- Nikita P

- Dec 29, 2025

- 2 min read

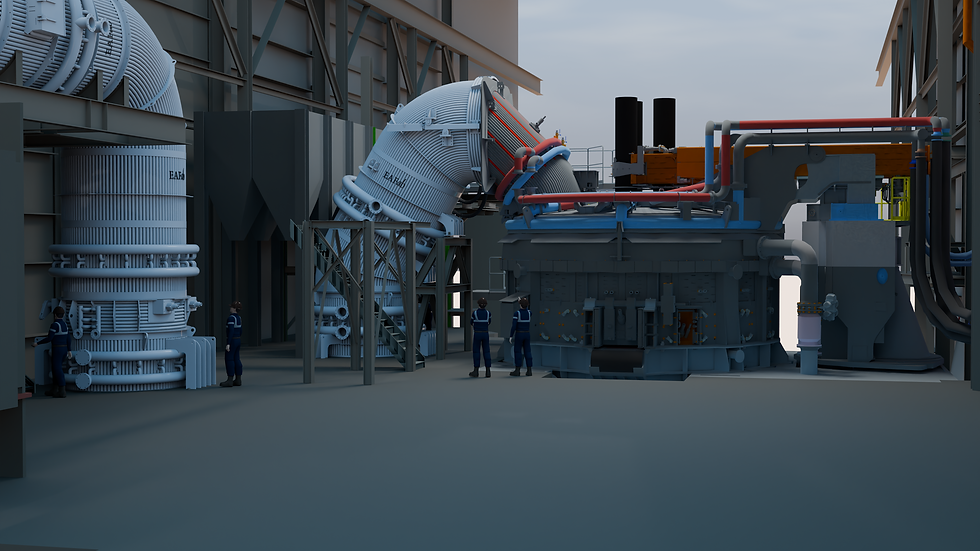

When people think of steelmaking, they picture massive furnaces, molten metal, and showers of sparks. But before all of that can happen, it must start with an essential piece of equipment: the scrap bucket. At EAFab, where advanced Electric Arc Furnace (EAF) technology melts scrap into new steel, we ensure the scrap bucket plays a critical, efficient role in every melting cycle.

What Is a Scrap Bucket?

The scrap bucket is designed to handle tons of scrap material and is manufactured to be strong, durable, and precisely engineered for its specific furnace application. As their size is dependent on the EAF's upper shell dimensions, scrap buckets can vastly range in size, with the average diameter spanning from 10 to 25 feet.

Although every steel producer has its own process, in general, it begins with:

Sorting the Scrap: The process begins in the scrap yard, where scrap metal is strategically and carefully sorted into charge piles that contain specific chemical percentages. These percentages are contingent on the mill's output and the steel grade it produces. After sorting, the processed charge pile is loaded into the scrap bucket.

Weighing the Charge: Each bucket is then weighed to ensure the exact amount of scrap is placed into the furnace; too much or too little can cause operational issues. The average weight of an EAF scrap bucket charge can range between 60 and 100 metric tons, with some furnace capacities reaching up to 400 tons.

Charging the Furnace: A crane then lifts the scrap bucket from its pail and transports it over the EAF. The furnace roof will then swing open, indicating that it is ready to receive the charge and start its heat cycle. EAFab's scrap bucket design utilizes a drop-bottom mechanism and is designed to only open and release scrap material when the EAF is in position for its next melting cycle. US steel mills with EAFs typically produce 15 to 25+ heats per day, with tap-to-tap times ranging from 45 to 60+ minutes per heat, depending on furnace size and efficiency.

Why the Scrap Bucket Matters

Without the scrap bucket, there is no melting cycle. It ensures:

Safe handling and transportation of heavy scrap

Consistent steel quality by enabling controlled material loading

Workflow routine, keeping things smooth and in order.

Final Thoughts

In the world of steelmaking, the scrap bucket might not get much attention, but without it, there’s no steelmaking. At EAFab, we ensure that it serves as the foundation of every successful heating cycle. Next time you see a pipe, car, bridge, or anything else made from steel, remember: it all started with the scrap bucket.

The contents of this blog were written, rendered, and produced by a Student Intern from our STEAM Program at Upper Saint Clair High School.

.png)

Comments